Slab-re saw Avangard-KS-50RG

You can buy a rib-humping machine from us, the price of the manufacturer. Own production, best delivery terms.

AvangardKS-50RGVideo of the vanguard-KS-50RG rib-humping machine

Video of the vanguard-KS-50RG rib-humping machine during operation.

2018-11-07T16:19:26

Balance processing

Video of the Avangard-KS-50RG rib-humping machine - balance processing.

2018-11-07T16:19:27

Video lines from SDB-260, MD-16, KS-50-RG machines

Video machines: Avangard-SDB-260, Avangard-MD-16, Avangard-KS-50-RG - balance processing line.

2019-04-25T11:58:35

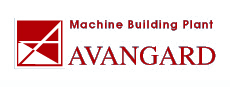

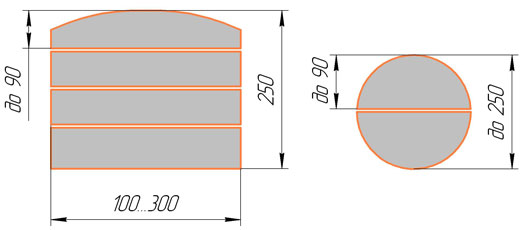

The KS-50RG slab re-saw is a modification of the KS-50 machines and is designed for sawing logging slab into an edged board in one pass. The machine can also perform the functions of re-saw and edge-trimming machines.

The machine includes a saw unit of the KS-50PK machine, mounted fixedly on the under frame. A chain conveyor with flat bearing elements is located under the saw unit. The conveyor is equipped with eight independent pneumatic clamps for raw materials to be sawn.

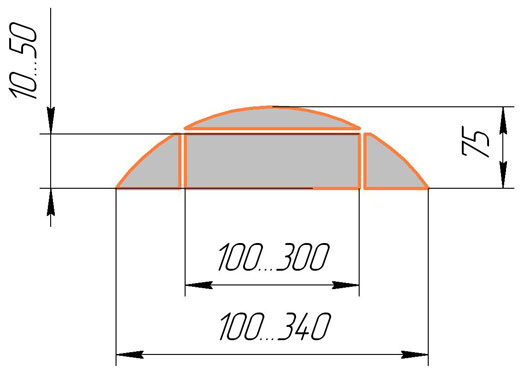

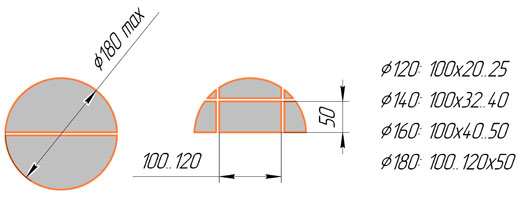

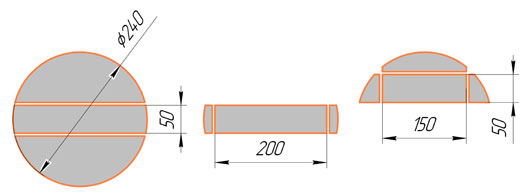

This design of the saw unit and conveyor allows you to cut raw materials both with a flat mounting surface (logging slab, board, timber), and also of circular cross-section (pulpwood, lumber log).

Horizontal sawing is performed with two circular saw blades with a diameter of 400 mm, and vertical sawing is performed with circular saw blades with a diameter of 250 mm. When performing sawing simultaneously with horizontal and vertical saw blades, at first, sawing is carried out with the help of horizontal saw blades and then with vertical ones, which allows you to remove wood scraps from the sawing area.

The distance between the vertical saw blades is continuously adjusted by means of a screw mechanism using a digital indicator that shows the actual distance between the saw blades.

The edge-trimming block with vertical saw blades can be brought into and out of operation by means of a lever.

Technical specifications of the Avangard- KS-50RG slab-re saw

| Parameter | Values |

|---|---|

| Maximum cutting width of horizontal saws, mm | 300 |

| The maximum height of a vertical cut of saws, mm | 55 |

| Maximum width of the processed hump, mm | 340 |

| The maximum thickness of the slab by the simultaneous operation of all saws, mm | 75 |

| Dimensions of the resulting edged boards: - width, mm - thickness, mm - length, m |

100...300 10...50 1,2...6,4 |

| Additional functions of the machine-sawing 3-and 4-edged bars, cross-section: - width, mm: - height, no more, mm: |

100...300 250 |

| Horizontal saws: - drive - power, kW - rotation speed, rpm - saws: quantity (pc.) x diameter (mm) |

electromotor 2×7,5 3000 2×400 |

| Vertical (edging) saws: - drive - power, kW - rotation speed, rpm - saws: quantity (pc) x diameter (mm) |

electromotor 5,5 3000 2×250 |

| Installation of horizontal saws on the size: - drive - drive power, kW - travel speed, mm/s |

electromotor 0,55 25 |

| Installation of vertical saws on the size: - drive - positioning |

manual digital indicator |

| Conveyor for feeding the workpiece to the saw: - drive - drive power, kW - feed speed, m/min |

electromotor 1,5 0…20 |

| Machine dimensions, W×H×D, no more, m | 1,5×2,3×4,3 |

| Machine weight, not more than, kg | 1900 |

In the summary table, you can compare the comparative characteristics for logging slab and pulpwood processing.