Chipper canter Avangard FBM-250

Milling and canting machine Avangard FBM-250 sequentially performs two operations: caning by milling and sawing the resulting gun carriage into edged sawn timber. The combination of these operations in one machine allows processing small-sized stock with a diameter of up to 250 mm into edged material in one pass. Favorable delivery terms, reasonable price.

AvangardFBM-250Milling and canting machine Avangard FBM-250 designed for processing small-sized wood into edged boards in one pass.

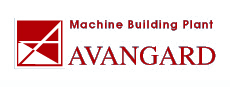

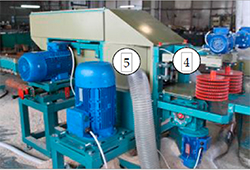

Milling and canting unit consists of two electric motors of 18 kW each, mounted on linear guides. Milling cutters are installed on the motor shafts, the design of which allows them to be fixed on the motor shaft in a given position, which ensures the initially symmetrical position of the cutters relative to the conveyor axis.

The installation of the cutters to the given size of the timber (carriage) is carried out by the operator manually by rotating the handwheel of the screw mechanism in a few seconds. The actual distance between the cutters is displayed on a digital indicator with an accuracy of 0.1 mm in the range from 60 to 220 mm. (In the basic configuration from 60 to 160 mm).

Two-shaft multi-rip block with vertical shafts. 6-8 saws can be installed on each shaft, depending on the thickness of the carriage. At the exit from the block, riving knives are installed, the lower one of which separates the slab and provides the supply of the sawn material to the receiving table with the flat surface of the sub-saddle board. In the basic configuration, two electric motors with a power of 22.5 kW each and saws with a diameter of 250 mm are installed in the multi-saw unit, which allows sawing a carriage with a thickness of up to 160 mm. The design features of the multi-saw unit allow you to install motors of higher power & ndash; up to 37.5 kW and saws with a diameter of up to 350 mm, which allows sawing carriages up to 220 mm thick.

Composite feeding conveyor of the machine. A loading conveyor element up to 6.25 m long is docked to the main conveyor located inside the bed. Raw materials are fed by a traction chain with hooks welded to it.

The block of drive hazelnuts provides a forced supply of the sawn material to the receiving table of the machine.

Technical characteristics of the Avangard FBM-250 milling and canting machine

| Diameter of the sawn logs | 80 – 250 mm |

| Workpiece length | 1 – 6,2 m |

| The width of the resulting edged board (timber) | 60 – 160 mm (220 mm)∗ |

| Working length of vertical saw shafts | 240 mm |

| Maximum milling layer with one cutter | 70 mm |

| Cutting capacity with circular saws | 3,2 mm |

| Circular saws diameter | 250 mm |

| Workpiece feed speed (continuously variable) | 0...10 m/min |

| Workpiece productivity | до 6 m3/hour |

| Electric motor parameters : - Milling unit - Multi rip block - Feeding conveyor - Drive unit |

2 × 15 kWt (3000 rpm ) 2 × 15 кВт (3000 rpm ) 2,2 kWt 2 × 0,37 kWt |

| Overall dimensions: - Machine without conveyor feed L×H×W - Loading length - Pick-up table length (optional) - Machine weight - Transport dimensions L×H×W |

2,8 × 2 × 1,7 m to 6,25 m 2 – 5 m 2000 kg 6,25 × 2,5 × 1,7 |

∗ when installing saws and motors of the appropriate diameter and power.

Basic delivery set:

- Feeding conveyor, length 3,0 m. – 1 pc.

(the length of the feeding conveyor can be increased at the request of the Customer ); - Complete machine (Milling and canting unit, multi rip block) – 1 pc.;

- Receiving table – 1pc.;

- Control panel – 1 pc.;

- Cutters – 1 set ;

- Saw blades Ø 250 mm – 20 pc.;

- Technical passport and operation manual – 1 copy.