Line for production of sip panels Avangard-LSP-1

The Avangard-LSP-1 line for the production of SIP panels has been developed for the production of sandwich panels. Delivery to any city in Russia, reasonable prices. We work without intermediaries.

AvangardLSP-1Video of the lines for the production of SIP panels Avangard-LSP-1

Video of the line for the production of SIP panels Avangard-LSP-1.

2018-11-07T16:19:27

The Avangard – LSP-1 line for production of structural insulating panels (SIP panels) is designed for production of sandwich panels based on OSB and expanded polystyrene. SIP sandwich panel is a monolithic structure obtained by gluing two OSB 3 plates and expanded polystyrene, used as heat and sound insulation material, by pressure.

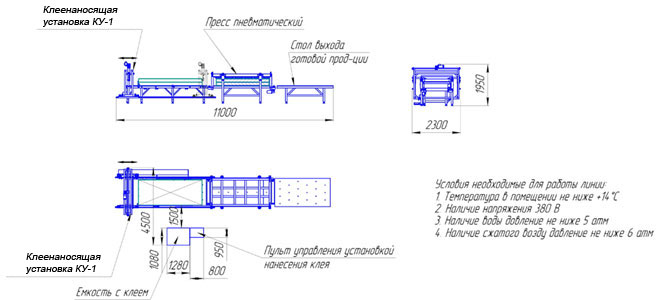

The Avangard-LSP-1 line consists of:

• glue application unit KU-1,

• guide (rail) track,

• mounting table,

• press,

• receiving table,

• control panel of the glue application unit KU-1.

The line operation

The oriented strand board (OSB) is put on the assembly table, placed according to the limit stops and fixed with eccentric clamps. The command to apply glue is generated from the control panel. At the same time, the glue application unit moves along the guide rails to the beginning of the glue application area. The glue supply is turned on, and thin strips of the glue is applied on the OSB surface with a constant step while moving along the guides. At the end of the glue application area, the glue application unit automatically stops and starts moving in the opposite direction. The water supply is turned on, water is sprayed on the surface of the plates through the nozzles, being a hardener for the glue. After placing the EPS foam on the plate, the processes of glue application and water supply are repeated. Then the OSB plate is placed on the foam, and the assembled sandwich panel is transported to the pressing area by a conveyor. After holding it under the press for about 10 minutes, the finished panel is transported to the receiving table, from which it is put manually or by means of lifting mechanisms with pneumatic pumps into storage in the workshop. Further on, the assembly, pressing and unloading processes are carried out simultaneously.

Technical specifications of the Avangard-LSP-1 line for production of sip panels

| Overall dimensions of the manufactured panels: width length height |

mm mm mm |

1250 2500…3000 100…230 |

| Productive capacity, pcs per shift | pcs per shift | up to 70 |

| Overall dimensions of the line: width length height |

m m m |

2,55 11,75 1,72 |

| Installed capacity electric pump unit (glue supply) movement mechanism of the KU-1 glue-bearing unit belt conveyor press water supply circulation pump |

kW kW kW kW kW |

2,5 1,1 0,55 0,75 0,1 |

| Air pressure required for operation | kgf / cm2 | 5,0 |

In the summary table, you can compare the technical characteristics of SIP panel production lines.