Machine Building Plant «Avangard»

Catalog of production

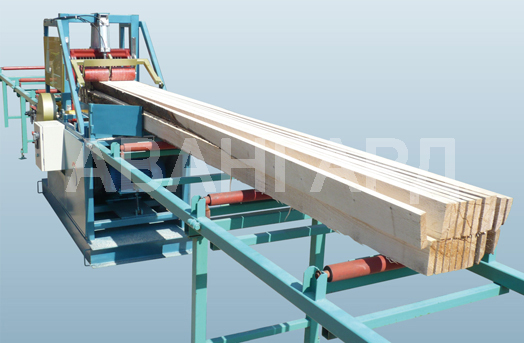

Power-saw benches

You can buy a sawmill from us, the price of the manufacturer. Own production, favorable delivery conditions, quality assurance.

AvangardLP, KS

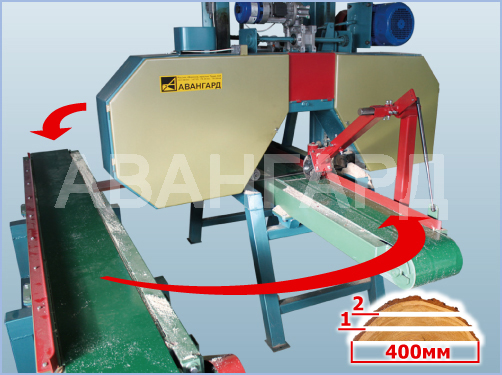

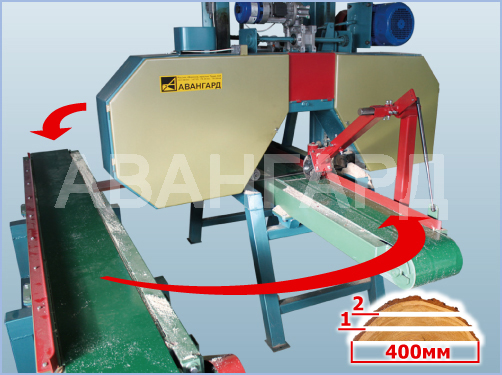

Band-dividing machines

You can buy a belt-dividing machine from us, the manufacturer's price. Own production, favorable delivery conditions, quality assurance.

AvangardLP

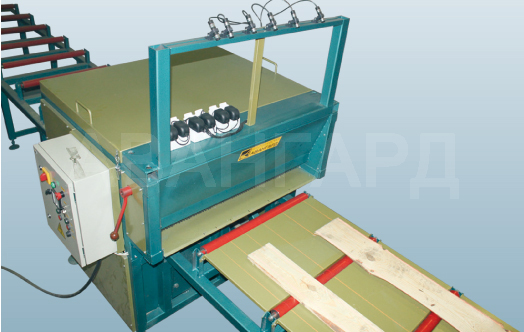

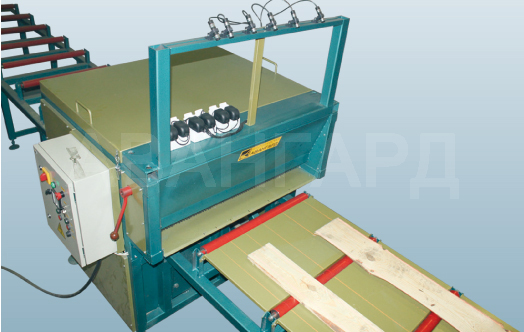

Multi blade saws

You can buy a multi-saw machine from us-the manufacturer's price. Own production, favorable delivery terms, quality assurance.

AvangardRM-50

Edge-trimming machines

You can buy an edging machine from us, the manufacturer's price. Own production, favorable delivery conditions, quality assurance.

AvangardSDK

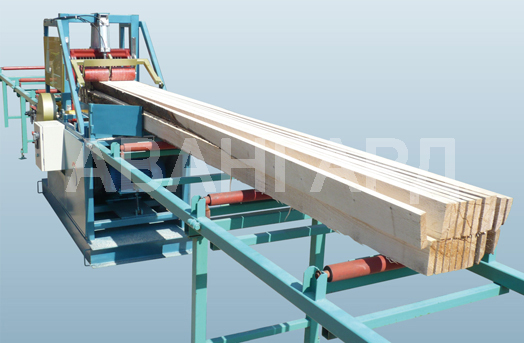

Log sawing machines

You can buy a paving machine from us, the manufacturer's price. Own production, favorable delivery conditions, quality assurance.

AvangardLP, SDB

Chipper canter Avangard FBM-250

Consecutively performs two operations: caning by milling and sawing the resulting gun carriage into edged sawn timber

AvangardFBM

Machines for logging slab and pulpwood processing

Here you can buy a machines for logging slab and pulpwood processing, the manufacturer's price. Own production, favorable delivery terms, quality assurance.

AvangardKS-50RG

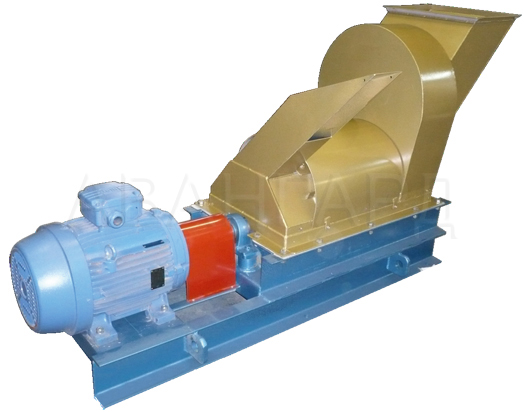

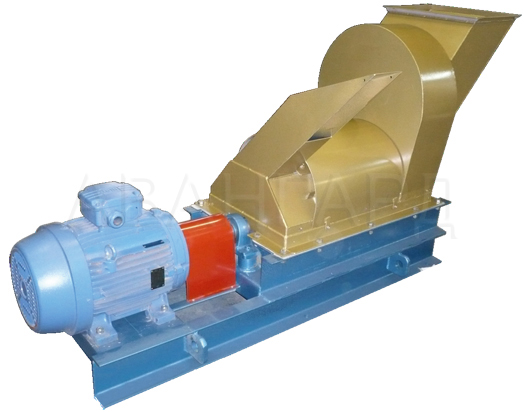

Trim soap grinders

Here you can buy a machine for processing wood waste, manufacturer's price. Own production, favorable delivery terms, quality assurance.

AvangardTSG

Equipment for assembly of pallets and machines for disassembly of pallets

Here You can buy a pallet assemble equipment and pallet dismantling machines, manufacturer's price. Own production, best delivery conditions.

AvangardPAT, PAJ, SRP

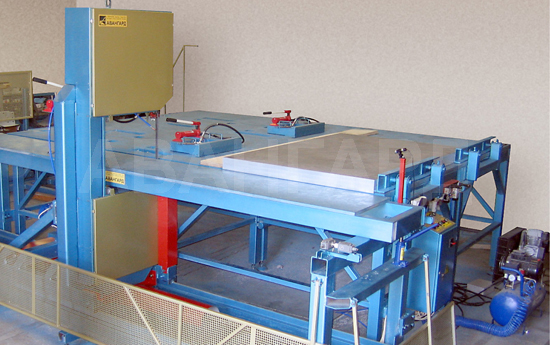

Mineral wool cutting equipment

Here you can buy equipment for cutting mineral wool, manufacturer's price. Own production, favorable delivery conditions, quality assurance

AvangardLP-80-TP, LS-50, RPM

Equipment for pipe cutting

You can buy pipe cutting equipment from us, manufacturer's price. Own production, favorable delivery conditions, quality assurance.

AvangardLS-50

Here you can buy equipment for cutting aluminum plates, manufacturer's price. Own production, favorable delivery conditions, quality assurance.

AvangardLS-50-AL

Here you can buy machines for cutting aerated concrete, manufacturer's price. Own production, favorable delivery conditions, quality assurance.

AvangardLRP, LS-50

Here you can buy equipment for the production of SIP panels-manufacturer's price. Own production, favorable terms of delivery, quality assurance.

AvangardLSP, LS-50-4, SVP

Storage decks, disconnectors, log sorting lines

You can buy drives, disconnectors, log sorting lines from us-the manufacturer's price. Own production, favorable delivery terms, quality assurance.

AvangardLD, LSL